Strong reliability.

Short light-off time.

Good sealing performance.

Performance and customer interface compatible with OEM products.

Strong anti-poisoning ability.

Stable signal.

Quick response.

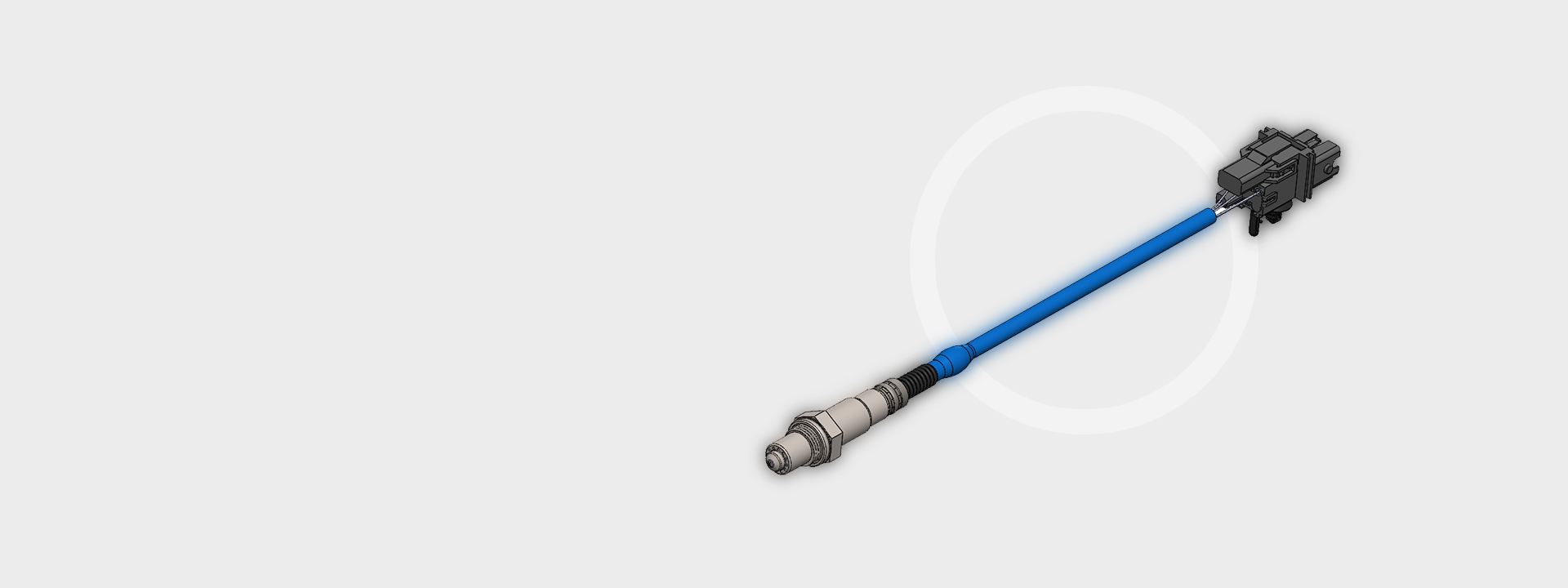

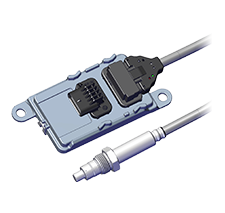

The wideband oxygen sensor is installed on exhaust pipeline before three-way catalyst as upstream oxygen sensor. It detects the oxygen concentration in exhaust and sends electrical signal to ECU. The ECU control the injection fuel amount achieving the optimal configuration of power and fuel economy while meeting emission requirements.

The structure of wideband oxygen sensor is mainly composed of diffusion chamber, reference chamber, pump cell, oxygen concentration cell and a heater. The wideband sensor applies voltage to the pump cell to generate pump current, so that the oxygen content on both sides of the oxygen concentration cell is consistent, and the voltage value is maintained at 0.45V (0.45V as reference). The rich fuel/air mixture will make the oxygen concentration cell voltage greater than 0.45V, and the sensor controller will apply the negative pump current Ip to pump oxygen into the diffusion chamber for chemical reaction, increase the O2 concentration of exhaust gas, and restore the voltage to 0.45V; When lean fuel/air mixture will make the oxygen concentration cell voltage less than 0.45V, the positive pump current Ip will be generated to pump the oxygen out of the diffusion chamber. When the fuel/air is ideal ratio for chemical reaction, the output voltage of the oxygen concentration cell is maintained at 0.45V. In this way, the wideband oxygen sensor reflects the oxygen ion concentration of exhaust gas and the degree of concentration through the value and direction of pump current.

Customized to customer choice of connection system.

Custom packaging can be provided to meet any need, please contact KESENS Engineering for details.