MEMS sensing technology

High accuracy, excellent long-term stability

Excellent EMC/ESD performance

Over voltage, reverse polarity and short circuit protection

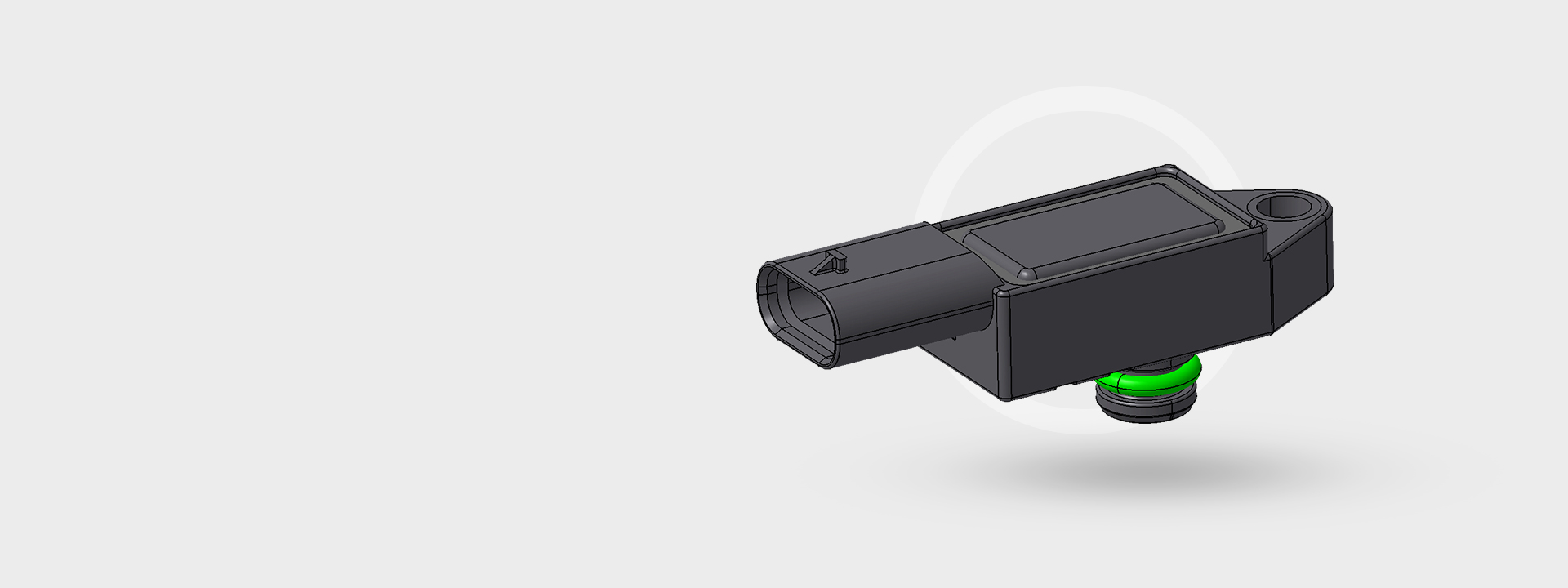

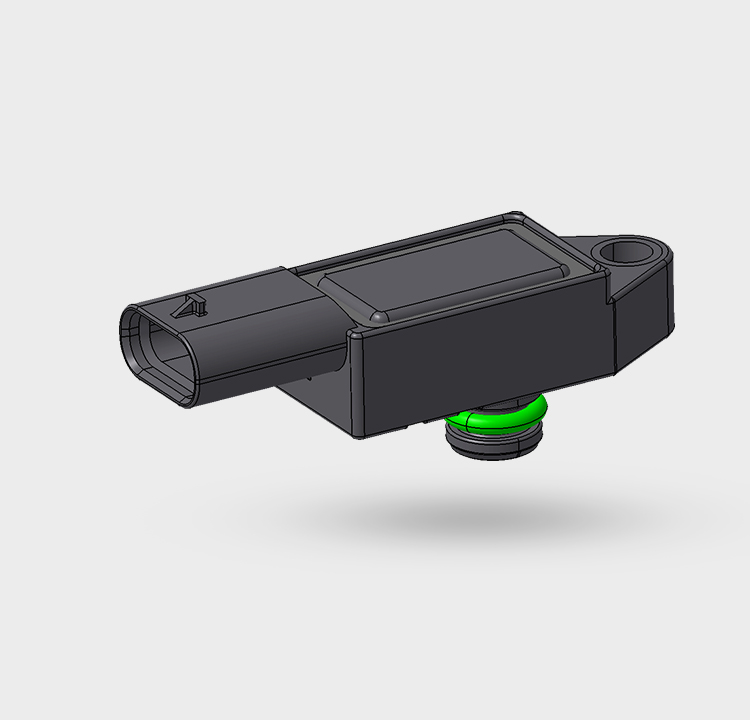

Customized pressure range, output curve, and housing

Excellent vibration resistance design

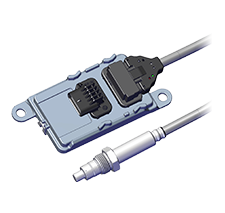

Modular product configuration

Excellent sealing and protective design

Check the pressure between the piston ring and the cylinder block in the crankcase. Prevent oil deterioration, crankshaft oil seal and crankcase gasket from leaking, and prevent fuel vapors from polluting the atmosphere.

Piston ring leakage fuel vapor (combustion gas composition, which enters the crankcase through the piston) generated during fuel combustion shall not be discharged into the air under any uncontrolled conditions. Therefore, on the one hand, the crankcase ventilation is used to re-introduce such vapors into the combustion system, on the other hand, it is responsible for controlling the negative pressure in the crankcase.

Measure the pressure difference between the pressure in the crankcase and the atmospheric pressure and send it to the engine control unit in the form of electrical signal. The engine control unit uses this signal to calculate and control the crankcase ventilation.

Customized to customer choice of connection system.

Custom packaging can be provided to meet any need, please contact KESENS Engineering for details.