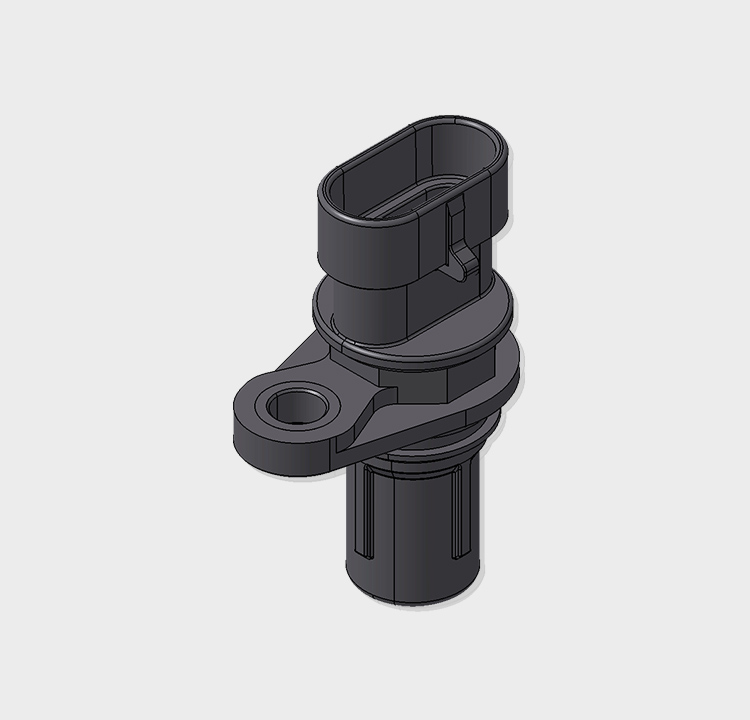

Hall effective sensing technology

Sealed non-contact, long service life, high reliability

Robust structural design suitable for harsh engine environments

High precision and good consistency

Good electromagnetic compatibility and anti-interference

Customized flexible connector outlet orientation and sensor mounting dimensions

Standard square wave output

Detect the rotation speed of the engine and the relative position of the piston when the crankshaft rotates; Determine the ignition time of the engine.

The crankshaft position sensor is installed on engine block facing to the flywheel and output the low/high voltage pulse to the flywheel teeth and slot accordingly. Ecu use the crank sensor output to determine the engine speed and the relative position of the piston; The engine control unit uses the information to control the ignition and fuel injection timing.

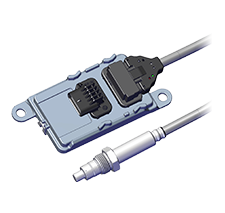

Customized to customer choice of connection system.

Custom packaging can be provided to meet any need, please contact KESENS Engineering for details.