MEMS sensing technology

Excellent EMC/ESD performance

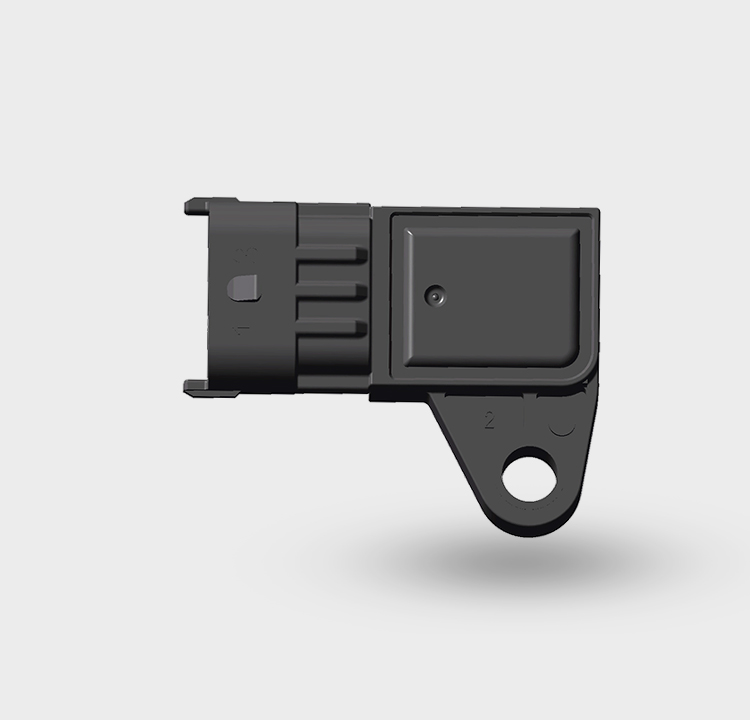

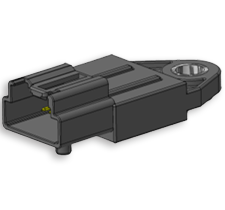

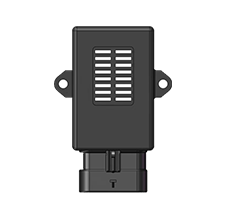

Customized pressure range, output curve, and housing design

Performance,appearance and customer interface compatible with major tier suppliers’ products

Excellent vibration resistance design

Modular product configuration

Excellent sealing and protective design

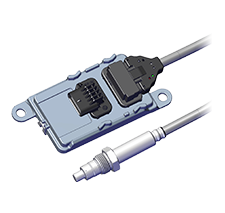

With information of purging line pressure sensor, ECU can obtain information to timely open the valve so that the activated carbon canister in the saturated adsorption state can regain the adsorption capacity.

The purging line pressure sensor converts the pressure of the desorption path into a voltage signal through the MEMS module inside the sensor. The sensor sends electrical signal to ECU so that ECU can get information to open the valve in time.

Customized to customer choice of connection system.

Custom packaging can be provided to meet any need, please contact KESENS Engineering for details.