MEMS sensing technology

High accuracy, excellent long-term stability

Intelligent zero compensation and temperature compensation

Excellent EMC/ESD performance

Overvoltage, reverse polarity and short circuit protection

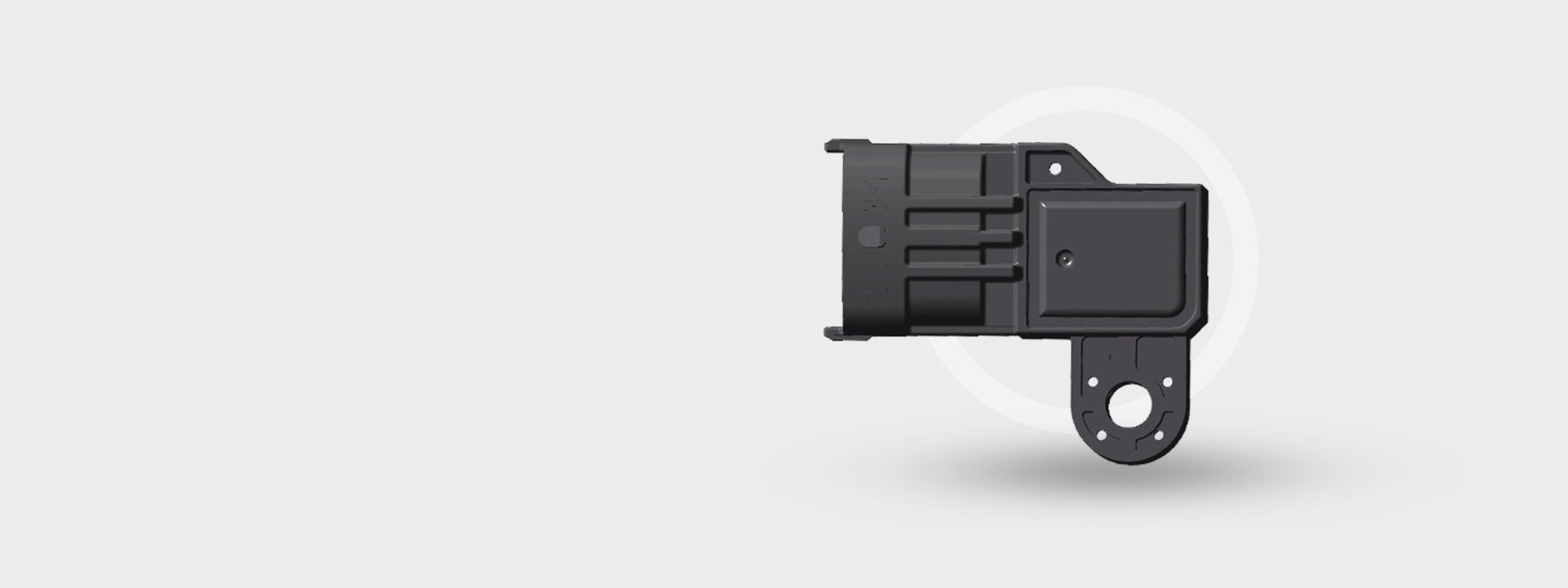

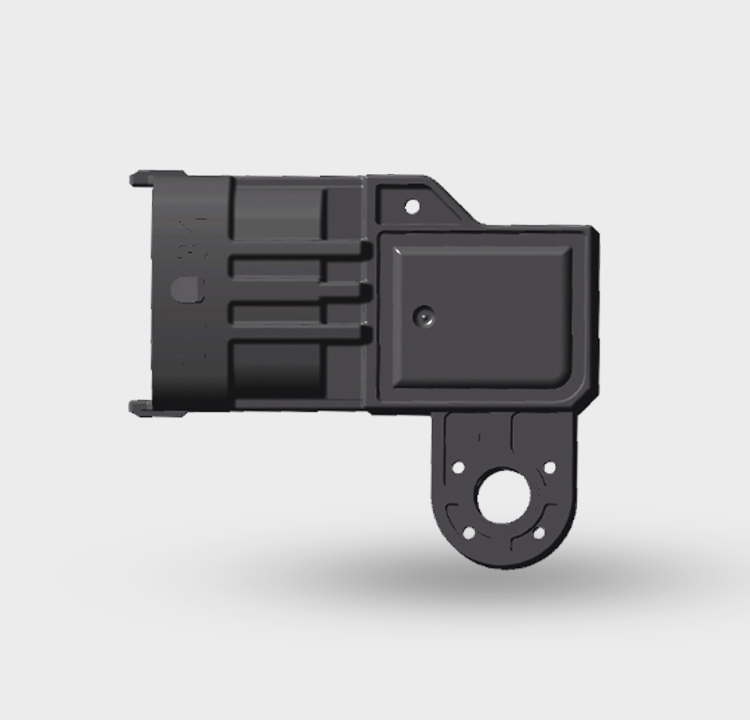

Customized design of pressure range, output curve, and external dimensions

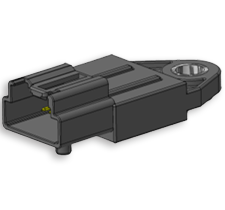

Single chip solution ,SMT for EMA fabrication process.

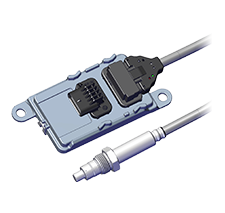

Design for EGR system harsh operation environment.

Different pressure ranges are available on customer request.

With information of TMAP sensor and the manifold and cylinder volume, ECU can calculate the intake air mass flow and ratio of air & fuel, increase or reduce fuel injecting time to get the optimal ratio of air & fuel.

According to the change of vacuum in intake manifold, the pressure part of intake temperature and pressure sensor converts into voltage signal from the change of internal resistance of sensor, which is used for ECU computer to correct fuel injection quantity and ignition timing angle. The temperature part consists of a negative temperature coefficient thermistor. When the temperature is high, the resistance decreases; when the temperature is low, the resistance increases. With the change of temperature resistance, the voltage changes, and the signal changes from 0V to 5V.

Customized to customer choice of connection system.

Custom packaging can be provided to meet any need, please contact KESENS Engineering for details.