The working temperature range is wide, from - 40 ℃ to 140 ℃, with full temperature compensation。

Fluorinated gel encapsulation protection to adapt to poor exhaust environment.

Excellent over and back pressure protection, back pressure - 24 V, over voltage 28 v.

Appearance and customer interface can be compatible with major tier 1 suppliers’ products.

SMT for EMA fabrication process.

According to customer requirements, a variety of ranges can be customized.

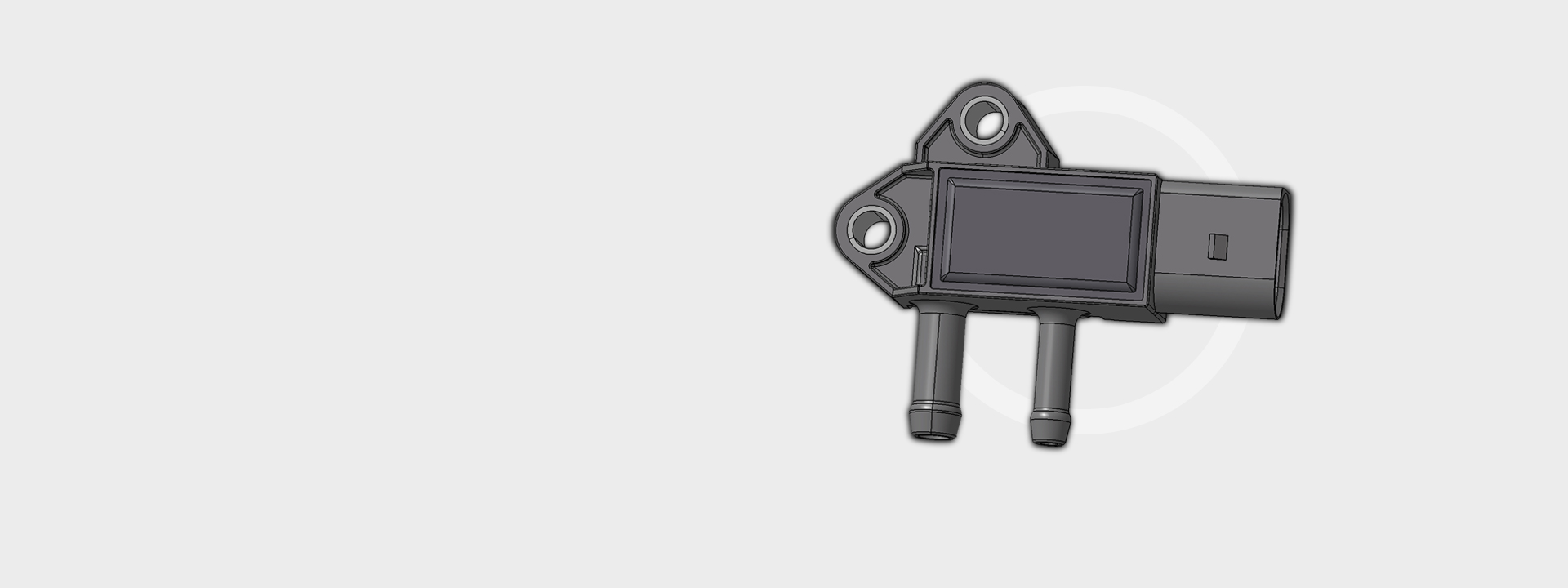

The differential pressure sensor detects the differential pressure between two ports of the particulate filter in the exhaust system and sends signal to ECU so that ECU control the appropriate regeneration time of the particulate filter for exhaust emission management, which can reduce the particulate matter by up to 90%.

The pressure sensitive unit of the DPF sensor is affected by the pressure change at both ends of the particulate trap, resulting in the change of the resistance value of the Wheatstone bridge, which is converted into a voltage signal. The signal is amplified and compensated by the signal conditioning circuit, and the pressure difference signal is sent to the ECU. The ECU judges the accumulation degree of particles in the trap according to the pressure difference, and determines the regeneration trigger time.

Customized to customer choice of connection system

Custom packaging can be provided to meet any need, please contact KESENS Engineering for details.